FlightWorks' RC department. Here you will find RC products and accessories in the future.

Vintage FPV racers (Discontinued)

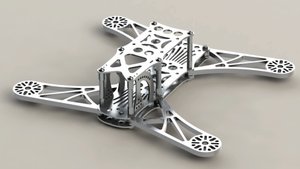

Frame Weight: 115g

Frame class: 220 “Slight long”

Prop. size: 5"

Motor size: M3 attached motors of choice

Power: Battery on top, or below if HDcam is used.

Propellers are limiting battery size on top.

Flight Cam: Optimized for foxeer series enclosed

cams. 15-80° angle supported.

Material:7075-T6 aerospace aluminium

BuildBlog: http://intofpv.com/t-flightworks-rebel-220

Photographer C. Eltvik

Frame Wight: 166g

Frame class: 250

Max. Prop. size: 6"

Motor size: M3 or M2 attached motors of choice.

Power: Up to 4S 1500 mAh depending on brand

housed inside frame.

Camera option: Tiestrap suspension or screw,

-10°<-> 60° angle.

Included: Frameparts, fasteners, spacers, ground cable shues.

Photographer C. Eltvik

Product profile

FlightWorks has been working several years with developing aerial photography platforms for own use. Advanced aerospace materials and cutting edge manufacturing technique among Sweden's leading industrial facilities has been used with great success.

After several non revenue carbon fibre and aluminium projects, the choice of a high strength aluminum 7075-T6 FPVracer has been chosen for sale.

Some of the benefits using high strength Aluminum:

•Product price can be kept to a minimum in relation to achieved volumes, design strength and quality.

•Comon ground for all elctronics is available in the frame, as in automotive industry. This saves weight, avoids cable congestion without the need of a PCB, and making the construction simple to build and maintain.

•Thanks to the metal's isotropic properties, more advanced shape can be achieved compared to carbon fibre structures in relation to cost. Aluminium is equally strong in any direction, as supposed to CF, which is only strong pulled in its fibre direction. As an example of a problem arising with CF plates, is drilled or milled screw and bolt holes close to edges. These are easily skewed out when subjected to high forces - this is because only the glue/resin in the CF plate is actually helping to hold bolts and other fasteners in the carbon fibre plate's plane.

•Parts are easily repaired by bending, should a hard crash result in a deformed part.

•Arms can be made aerodynamically transparent for the propwash, creating improved thrust compared to a flat, rather wide carbon fibre arm.

•Superior cooling of attached components due to the excellent heat transfer propperties aluminium holds. This applies especially to motors running at high power.